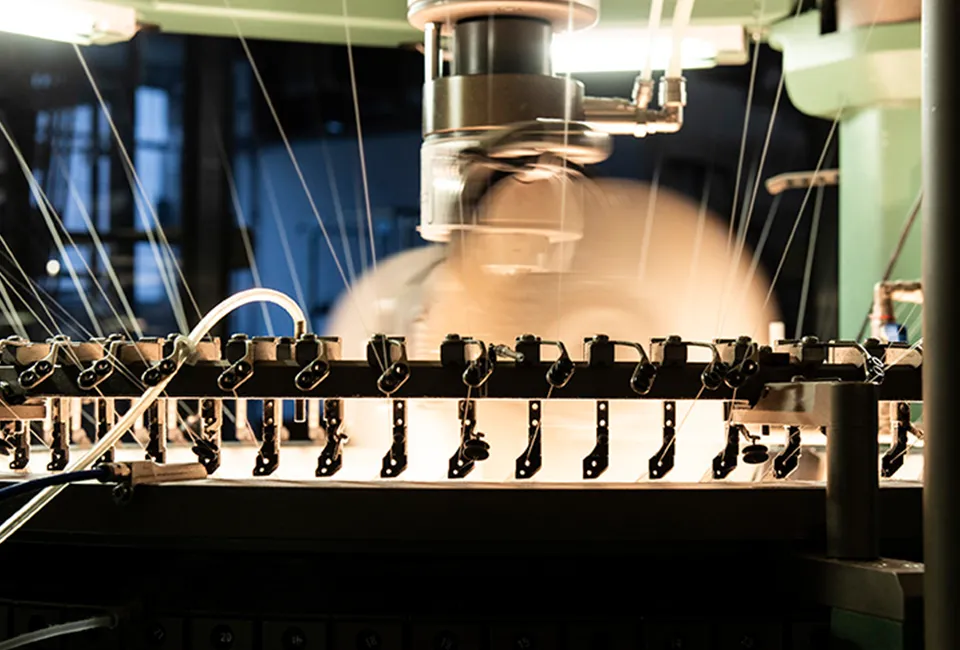

Raw material research

The accurate and careful search for raw materials, especially yarns, is a fundamental pillar in the creation of high quality products for La Methode.

This analysis not only helps to ensure the durability of manufactured products, but also plays a crucial role in preserving and protecting the entire production chain, meeting consumer expectations in terms of performance, but also helps to build a reputation of reliability and excellence for the brand.

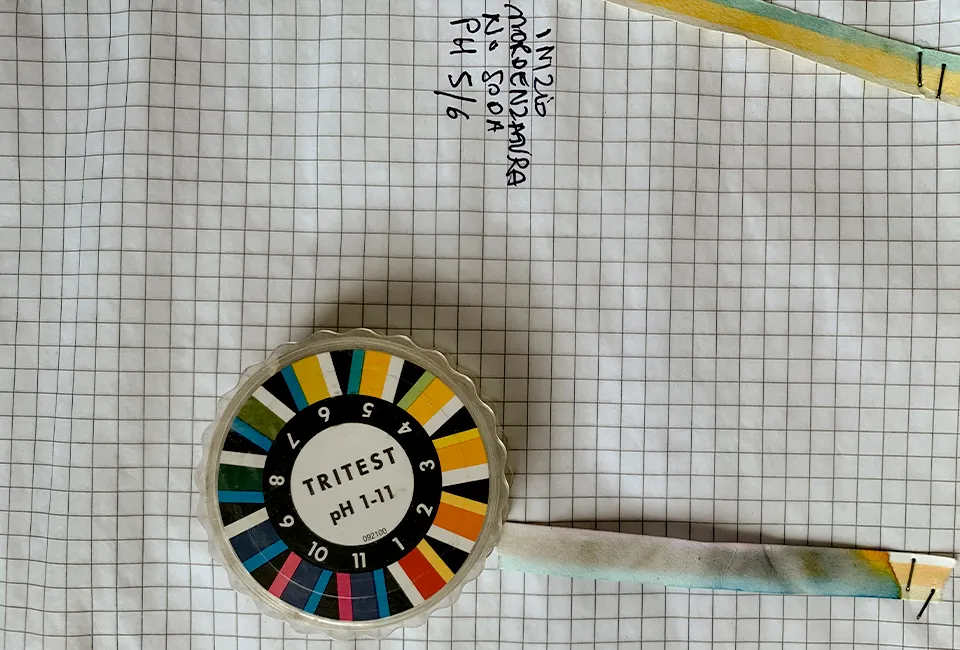

Supima cotton, Sea Island, textile hemp and nettle spun and twisted according to our specifications are the fibres identified as suitable for the project, ensuring that we can measure their impact while protecting their longevity.

Let us also not forget our secondary raw materials: fabrics in stock, whether returned or unsold, are always of excellent quality.